|

|

PDF ATS617LSG Data sheet ( Hoja de datos )

| Número de pieza | ATS617LSG | |

| Descripción | Differential Hall Effect Gear Tooth Sensor | |

| Fabricantes | Allegro Micro Systems | |

| Logotipo |  |

|

Hay una vista previa y un enlace de descarga de ATS617LSG (archivo pdf) en la parte inferior de esta página. Total 16 Páginas | ||

|

No Preview Available !

ATS617LSG

Dynamic, Self-Calibrating, Peak-Detecting, Differential

Hall Effect Gear Tooth Sensor

Features and Benefits

www.da▪taSsehlef-ect4auli.bcoramting for tight timing accuracy

▪ First-tooth detection

▪ Immunity to air gap variation and system offsets

▪ Immunity to signature tooth offsets

▪ Integrated capacitor provides analog peak and

valley information

▪ Low timing-accuracy drift with temperature changes

▪ Low radiated emissions

▪ Integrated, series resistor on VCC pin for improved

transient immunity

▪ Large air gap capability

▪ Small, integrated package

▪ Optimized magnetic circuit

▪ Undervoltage lockout (UVLO)

▪ Wide operating voltage range

Package: 4-pin SIP (suffix SG)

Description

The ATS617 gear-tooth sensor is a peak-detecting device

that uses automatic gain control and an integrated capaci-

tor to provide extremely accurate gear edge detection down

to low operating speeds. Each sensor module consists of a

high-temperature plastic shell that holds together a samar-

ium-cobalt magnet, a pole piece, and a differential open-

collector Hall IC that has been optimized to the magnetic

circuit. This small package can be easily assembled and

used in conjunction with a wide variety of gear shapes and

sizes.

The gear-sensing technology used for this sensor module is

Hall-effect based. The sensor incorporates a dual-element

Hall IC that switches in response to differential magnetic

signals created by ferrous targets. The sophisticated pro-

cessing circuitry contains an A-to-D converter that self-

calibrates (normalizes) the internal gain of the device to

minimize the effect of air gap variations. The patented

peak-detecting filter circuit provides immunity to magnet

and system offsets and has the ability to discriminate rela-

tively fast changes such as those caused by tilt, gear wobble,

and eccentricities. This easy-to-integrate solution provides

first falling edge detection and stable operation to extremely

low rpm. The ATS617 can be used as a replacement for the

ATS616.

Not to scale

Continued on the next page…

Functional Block Diagram

VCC

Hall

Amp

Hall

Amp

RS Voltage

Regulator

UVLO

Gain

Reference

Generator

Power-On

Logic

Tooth and Valley

Comparator

Track and

Hold

Current

Limit

Track and

Hold

VOUT

ATS617LSG-DS

GND

(Recommended)

TEST

1 page

ATS617LSG

Dynamic, Self-Calibrating, Peak-Detecting, Differential

Hall Effect Gear Tooth Sensor

www.datasheet4u.com

Reference Target (Gear) Information

REFERENCE TARGET 60+2

Characteristics

Symbol

Test Conditions

Typ.

Outside Diameter

Face Width

Angular Tooth

Thickness

Signature Region

Angular Tooth

Thickness

Angular Valley

Thickness

Tooth Whole Depth

Material

Do Outside diameter of target

120

F

Breadth of tooth, with respect

to sensor

6

t

Length of tooth, with respect

to sensor; measured at Do

3

Length of signature tooth,

tSIG with respect to sensor; mea- 15

sured at Do

tv

Length of valley, with respect

to sensor; measured at Do

3

ht 3

Low Carbon Steel

–

Units

mm

mm

deg.

deg.

deg.

mm

–

Symbol Key

t Do

ht

tSIG

F

tv

Air Gap

Branded Face of Sensor

Signature Region

Pin 4

Pin 1

Branded Face

of Sensor

Reference Target

60+2

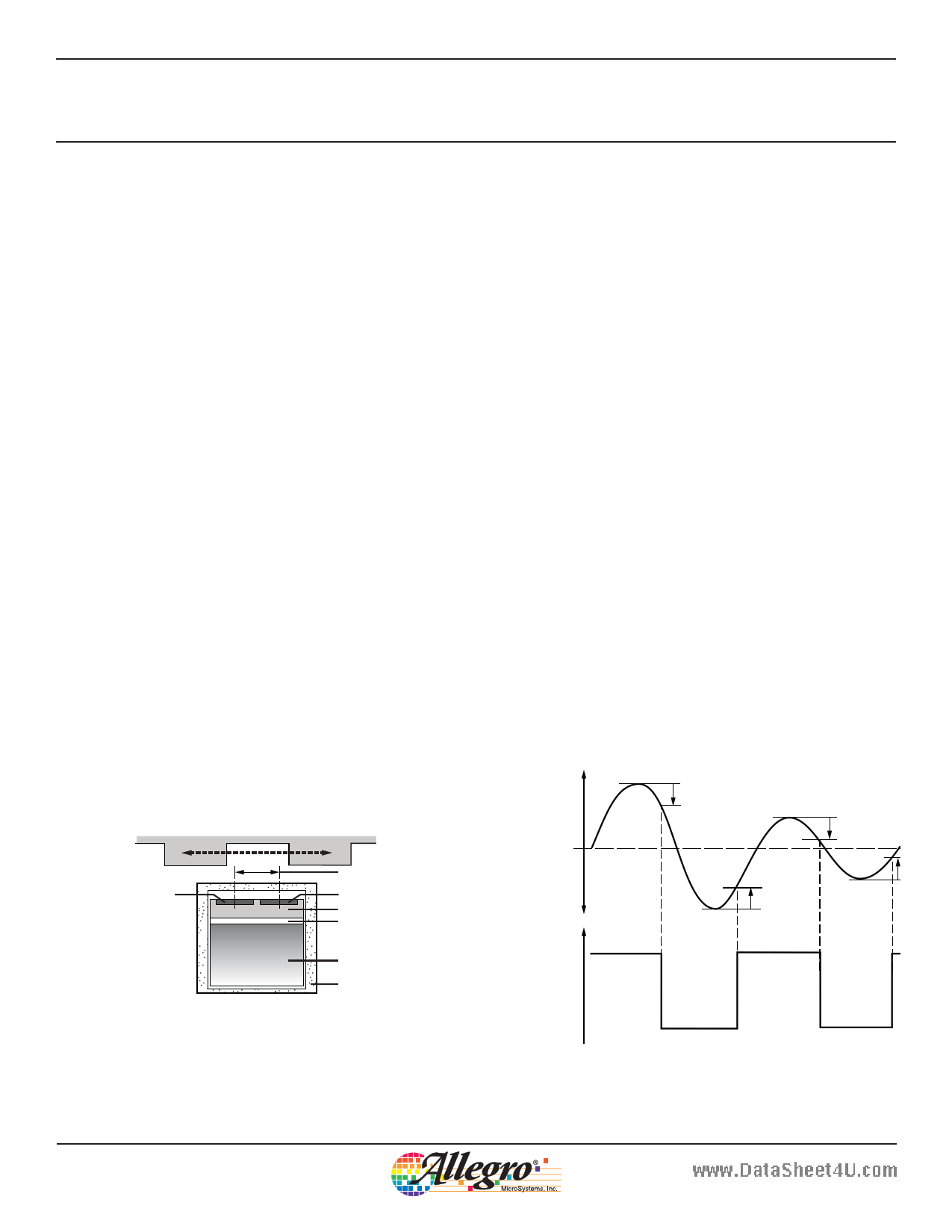

Figure 1. Configuration with Radial-Tooth Reference Target

Allegro MicroSystems, Inc.

115 Northeast Cutoff

Worcester, Massachusetts 01615-0036 U.S.A.

1.508.853.5000; www.allegromicro.com

5

5 Page

ATS617LSG

Dynamic, Self-Calibrating, Peak-Detecting, Differential

Hall Effect Gear Tooth Sensor

Functional Description

www.datasheet4u.com

Assembly Description The ATS617 gear-tooth sensor is a

Hall IC/magnet configuration that is fully optimized to pro-

vide detection of gear tooth edges. This sensor is packaged in a

molded miniature plastic body that has been optimized for size,

ease of assembly, and manufacturability. High operating tem-

perature materials are used in all aspects of construction.

After proper power is applied to the component, the sensor is

capable of instantly providing digital information that is repre-

sentative of the profile of a rotating gear. No additional optimi-

zation or processing circuitry is required. This ease of use should

reduce design time and incremental assembly costs for most

applications.

Sensing Technology The gear tooth sensor module contains

a single-chip differential Hall effect sensor IC, a samarium

cobalt magnet, and a flat ferrous pole piece (figure 2). The Hall

IC consists of 2 Hall elements (spaced 2.2 mm apart) located so

as to measure the magnetic gradient created by the passing of a

ferrous object. The two elements measure the magnetic gradient

and convert it to an analog voltage that is then processed in order

to provide a digital output signal.

The Hall IC is self-calibrating and also possesses a tempera-

ture compensated amplifier and offset cancellation circuitry. Its

voltage regulator provides supply noise rejection throughout the

operating voltage range. Changes in temperature do not greatly

affect this device due to the stable amplifier design and the offset

rejection circuitry. The Hall transducers and signal processing

electronics are integrated on the same silicon substrate, using a

proprietary BiCMOS process.

Internal Electronics The processing circuit uses a patented

peak detection scheme to eliminate magnet and system offsets.

This technique allows dynamic coupling and filtering of offsets

without the power-up and settling time disadvantages of classical

high-pass filtering schemes. The peak signal of every tooth and

valley is detected by the filter and is used to provide an instant

reference for the operate and release point comparator. In this

manner, the thresholds are adapted and referenced to individual

signal peaks and valleys, providing immunity to zero line varia-

tion from installation inaccuracies (tilt, rotation, and off-center

placement), as well as for variations caused by target and shaft

eccentricities.

The ATS617 also includes self-calibration circuitry that is

engaged at power on. The signal amplitude is measured, and

then the device gain is normalized. In this manner switchpoint

drift versus air gap is minimized, and excellent timing accuracy

can be achieved.

The AGC (Automatic Gain Control) circuitry, in conjunction

with a unique hysteresis circuit, also eliminates the effect of gear

edge overshoot as well as increases the immunity to false switch-

ing caused by gear tooth anomalies at close air gaps. The AGC

circuit sets the gain of the device after power-on.

Target (Gear)

Hall Element 2

Dual-Element

Hall Effect Device

(Pin n >1 Side)

South Pole

North Pole

Element Pitch

Hall Element 1

Hall IC

(CPoolnecPeinetcraetor)

Back-biasing Magnet

Case

(Pin 1 Side)

Figure 2. Relative motion of the target is detected by the dual Hall ele-

ments mounted on the Hall IC.

V+

Differential

Input Signal

VPROC

0

V–

BOP

BOP

BRP

BRP

VCC

Device Output

VOUT

VOUT(sat)

Figure 3. The peaks in the resulting differential signal are used to set the

operate, BOP, and release, BRP, switchpoints.

Allegro MicroSystems, Inc.

115 Northeast Cutoff

Worcester, Massachusetts 01615-0036 U.S.A.

1.508.853.5000; www.allegromicro.com

11

11 Page | ||

| Páginas | Total 16 Páginas | |

| PDF Descargar | [ Datasheet ATS617LSG.PDF ] | |

Hoja de datos destacado

| Número de pieza | Descripción | Fabricantes |

| ATS617LSG | Differential Hall Effect Gear Tooth Sensor | Allegro Micro Systems |

| Número de pieza | Descripción | Fabricantes |

| SLA6805M | High Voltage 3 phase Motor Driver IC. |

Sanken |

| SDC1742 | 12- and 14-Bit Hybrid Synchro / Resolver-to-Digital Converters. |

Analog Devices |

|

DataSheet.es es una pagina web que funciona como un repositorio de manuales o hoja de datos de muchos de los productos más populares, |

| DataSheet.es | 2020 | Privacy Policy | Contacto | Buscar |