|

|

PDF N-3406-2 Data sheet ( Hoja de datos )

| Número de pieza | N-3406-2 | |

| Descripción | (N-Series) Motors Brushless Servo Motors | |

| Fabricantes | Electro Craft | |

| Logotipo |  |

|

Hay una vista previa y un enlace de descarga de N-3406-2 (archivo pdf) en la parte inferior de esta página. Total 12 Páginas | ||

|

No Preview Available !

www.DataSheet4U.com

N-Series Motors

Brushless Servo Motors

N-2302-1, N-2304-1,

N-3406-2, N-3412-2,

N-4214-2, N-4220-2,

N-5630-2, N-5637-2,

N-5647-2

Electro-Craft Motion Control

6950 Washington Avenue South

Eden Prairie, MN 55344

612-942-3600

THE RIGHT COMPANY. THE RIGHT SOLUTION.

DataSheet4 U .com

1 page

Motor Dimensions

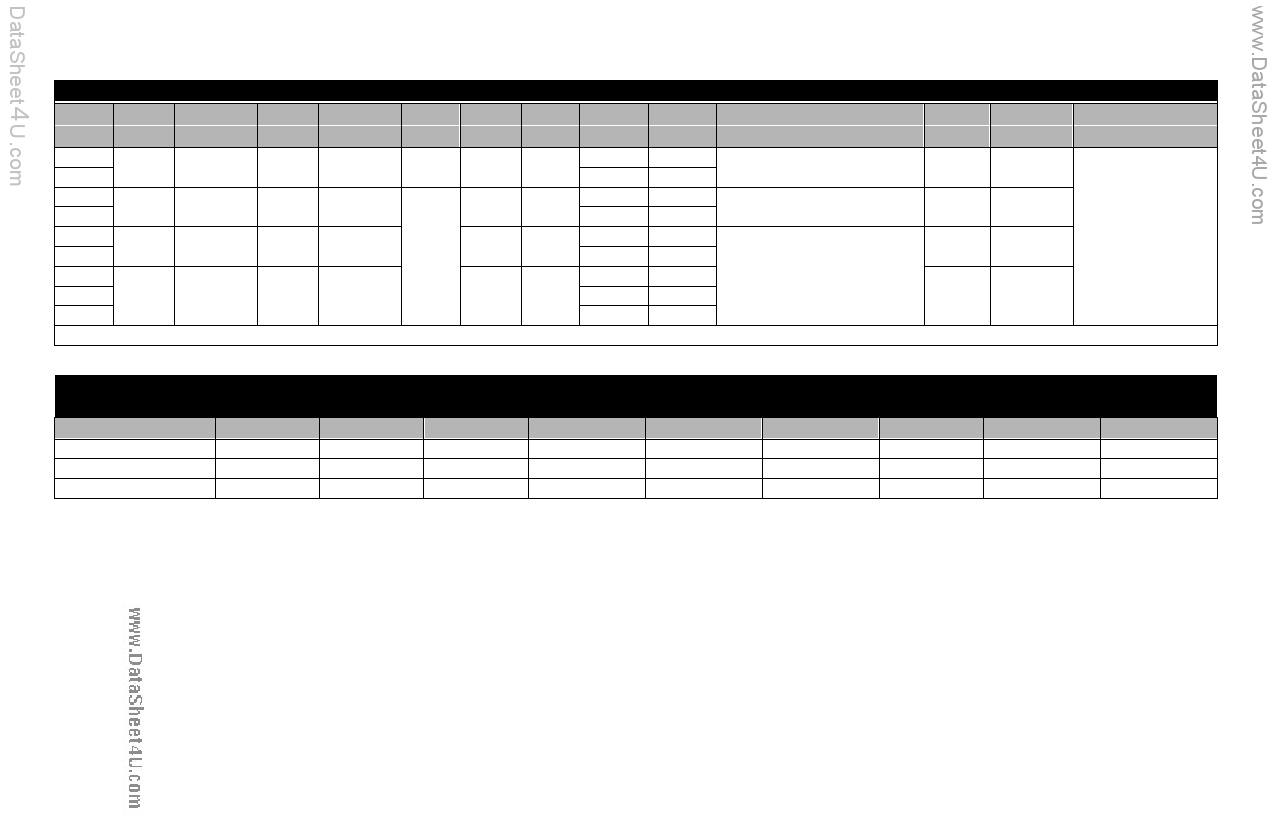

MOTOR DIMENSIONS

Motor AB AH AJ AK BB BE BF L L Brake

Model mm/in mm/in mm/in mm/in mm/in mm/in mm/in mm/in mm/in

N-2302 70/2.75 21/0.81 (1) 67/2.63 38/1.50 (2) 2/.09 7/0.28 5/0.21 118/4.63 161/6.32

N-2304

156/6.13 199/7.82

N-3406 63/2.48 30/1.19 (1) 98/3.88 73/2.88 (4) 3/.12 8/0.32 6/0.22 144/5.67 193/7.59

N-3412

169/6.67 218/8.59

N-4214 62/2.45 35/1.38 (1) 126/4.95 56/2.19 (7)

10/0.39 7/0.28 174/6.85 219/8.63

N-4220

199/7.85 245/9.63

N-5630 75/2.96 50/1.97 (1) 149/5.88 114/4.50 (8)

N-5637

12/0.47 0.375 in 199/7.83 256/10.06

UNC 224/8.83 281/11.06

N-5647

250/9.83 306/12.06

NOTE: Motors are manufactured to inch dimensions. Millimeter dimensions are approximate conversions from inches.

S

mm/in

NA

3.2 X 3.2 /0.125 X 0.125 (5)

4.8 X 4.8 /0.1875 X 0.1875 (5)

U

mm/in

6/.25 (3)

13/.5 (3)

16/.63 (3)

19/.75 (3)

XD

mm/in

NA

19/0.75 (6)

24/0.94 (6)

38/1.50 (6)

TOLERANCES

mm inches

1 -0.03 -0.00012

2 -0.01 -0.0004

3 ±0.5 ±0.0196

4 ±0.2 ±0.0079

5 -0.035 -0.0014

6 -0.013 -0.0051

7 -0.016

-0.006

8 -0.046 -0.0181

Connector

Brake (mm/in)

Power (mm/in)

Encoder (mm/in)

N-2302

105/4.13

62/2.43

145/5.71

N-2304

143/5.63

100/3.93

183/7.22

SUPPLEMENTAL MOTOR DIMENSIONS

Length, from motor faceplate to center of connectors

N-3406

N-3412

N-4214

N-4220

118/4.66

144/5.66

145/5.7

170/67

173/6.81

198/7.81

198/7.79

223/8.79

173/6.81

198/7.81

198/7.79

223/8.79

N-5630

176/6.94

235/9.25

235/9.25

N-5637

202/7.94

260/10.25

260/10.25

N-5647

227/8.94

286/11.25

286/11.25

5 Page

www.DataSheet4U.com

Motor Installation

Observe the following installation guidelines and those in the Product Notice:

WARNING: Motors and linkages must be securely mounted for a system

! to be operational. Disassembled equipment should be appropriately iden-

tified (tagged-out) and access to electrical power restricted (locked-out).

Failure to observe these safety procedures could result in personal injury

and damage to equipment.

1. Do not run motors that are not properly mounted. Attach all power and data cables after the

motor is mounted.

2. Mount motors with connectors pointing downward and use a drip loop in the cable to keep liq-

uids flowing away from the connectors.

3. Consider motor case temperature if necessary to safeguard operator and maintenance staff.

Maximum case temperature is approximately 100°C (212°F) for a motor used at continuous rat-

ing in a 40°C ambient temperature.

4. The installer must comply with all local regulations and should use equipment and installation

practices that promote electromagnetic compatibility and safety.

Preventing Electrical Noise

ElectroMagnetic Interference (EMI), commonly called “noise”, may adversely impact motor perfor-

mance by inducing stray signals. Effective techniques to counter EMI include filtering the AC power,

shielding and separating signal carrying lines, and practicing good grounding techniques. Effective

AC power filtering can be achieved through the use of isolated AC power transformers or properly

installed AC line filters. Physically separate signal lines from motor cabling and power wiring; do

not parallel signal wires with motor or power wires or route signal wires over the vent openings of

servo drives. Ground all equipment using a single-point parallel ground system that employs ground

bus bars or straps. If necessary, use electrical noise remediation techniques to mitigate EMI in “noisy”

environments.

Knowledgable cable routing and careful cable construction improves system electromagnetic com-

patibility (EMC). General cable build and installation guidelines include:

1. Keep wire lengths as short as physically possible.

2. Route signal cables (encoder, serial, analog) away from motor and power wiring.

3. Separate cables by 1 foot minimum for every 30 feet of parallel run.

4. Ground both ends of the encoder cable and twist the signal wire pairs.

5. Use shielded motor cables when necessary to prevent electromagnetic interference (EMI) with

other equipment.

Couplings and Pulleys

Mechanical connections to the motor shaft, such as couplings and pulleys, require a rigid coupling

or a reinforced timing belt. The high dynamic performance of servo motors can cause couplings,

pulleys or belts to loosen or slip over time. A loose or slipping connection will cause system instability

and may damage the motor shaft and keyway. All connections between the system and the servo

motor shaft must be rigid to achieve acceptable response from the system. Connections should be

periodically inspected to verify the rigidity.

When mounting couplings or pulleys to the motor shaft, ensure that the connections are properly

aligned and that axial and radial loads are within the specifications of the motor. The section “Load

Force Ratings” provides guidelines to achieve 20,000 hours of bearing life. Additional information

about load force ratings, including graphical depiction of varied load ratings and bearing life, is

available for any motor from the Technical Support groups listed on the back cover.

DataSheet4 U .com

11 Page | ||

| Páginas | Total 12 Páginas | |

| PDF Descargar | [ Datasheet N-3406-2.PDF ] | |

Hoja de datos destacado

| Número de pieza | Descripción | Fabricantes |

| N-3406-2 | (N-Series) Motors Brushless Servo Motors | Electro Craft |

| N-3406-2-xxxAA | MPN Motors | Parker |

| Número de pieza | Descripción | Fabricantes |

| SLA6805M | High Voltage 3 phase Motor Driver IC. |

Sanken |

| SDC1742 | 12- and 14-Bit Hybrid Synchro / Resolver-to-Digital Converters. |

Analog Devices |

|

DataSheet.es es una pagina web que funciona como un repositorio de manuales o hoja de datos de muchos de los productos más populares, |

| DataSheet.es | 2020 | Privacy Policy | Contacto | Buscar |